Improving Profit Margins with HVAC Estimating Software

Every HVAC contractor knows the chaos of early-morning calls, a technician calling out sick, and a customer following up on an invoice that’s still pending.

By midday, schedules have already changed multiple times, and yesterday’s paperwork is still waiting for attention. This constant juggling act is where many service businesses quietly lose time, efficiency, and revenue.

Modern HVAC software is designed to eliminate that friction by bringing field crews, office teams, and customers onto one connected system, turning daily firefighting into a more predictable, streamlined workflow.

Why HVAC Estimating Software is Key to Accurate Estimates and Higher Profit Margins

HVAC Estimating Software helps contractors optimize estimation workflows, reduce errors, and improve profitability. By providing tools for digital takeoffs, material cost tracking, and labor rate management, estimates remain precise and reliable.

This software also enables faster proposal generation, better coordination between office and field teams, and easy access to historical project data, allowing contractors to manage higher project volumes efficiently.

In this blog, we’ll explore how HVAC estimating software transforms the way contractors plan, price, and manage projects. You’ll learn how modern tools streamline workflows, reduce costly errors, and help teams make smarter, data-driven decisions while handling more jobs efficiently.

Key Takeaways

- Estimating tools streamline the estimating workflow, enabling reliable estimates and effective management of material costs and workforce costs.

- Modern HVAC tools support digital plans, automated takeoffs, and faster proposals, helping contractors take on additional projects in less time.

- By centralizing data and integrating with QuickBooks, this solution improves workflow, reduces overhead, and ensures precision.

- User-friendly HVAC platforms help ductwork contractors and technicians optimize planning, track costs, and maintain overall profitability.

If you're ready to price jobs with confidence and scale without guesswork, schedule a quick demo with HVACBase and start turning reliable estimates into measurable profits.

Why Inaccurate Estimates Reduce HVAC Profitability?

When estimating processes are inefficient, even small errors can significantly affect profitability. One of the most common issues is margin erosion from missed line items.

When labor hours are underestimated, material quantities are overlooked, or equipment costs are partially accounted for, the job may still get approved, but the profit disappears during execution. These missed details rarely trigger immediate alarms, yet they directly reduce the final margin.

Common Causes of Inaccurate Estimates

Many of these challenges stem from gaps in how estimates are created, updated, and managed across teams.

1. Manual Calculations and Spreadsheet-Based Estimating Software

Spreadsheets are prone to human error and require frequent manual updates, increasing the risk of mistakes.

It creates problems like:

- Typing errors and miscalculations

- Conflicting versions across team members

- Time wasted updating multiple files

2. Estimates Based on Outdated Pricing

When estimates rely on old or static pricing, accuracy quickly breaks down. Material costs, supplier rates, and equipment prices change frequently, and without real-time updates, estimates fail to reflect actual project costs. This gap often shows up later as budget overruns or reduced margins.

Common challenges include:

- Supplier price updates are not syncing with active estimates

- Limited flexibility to adjust quotes when costs rise unexpectedly

- Increased chances of underquoting and absorbing losses during execution

3. Lack of a Standardized HVAC Estimating Process

Without a shared estimating framework, teams often rely on personal judgment or past habits. While experience matters, inconsistent methods make it difficult to deliver reliable and repeatable estimates across projects.

This typically results in:

- Different assumptions about labor hours, materials, and scope

- Inconsistent pricing for similar jobs, confusing both teams and customers

- Limited visibility into estimating performance, making it harder to refine and improve accuracy over time

To know more about the common mistakes that occur in HVAC estimates, dive deeper here: Common HVAC Estimate Mistakes to Avoid.

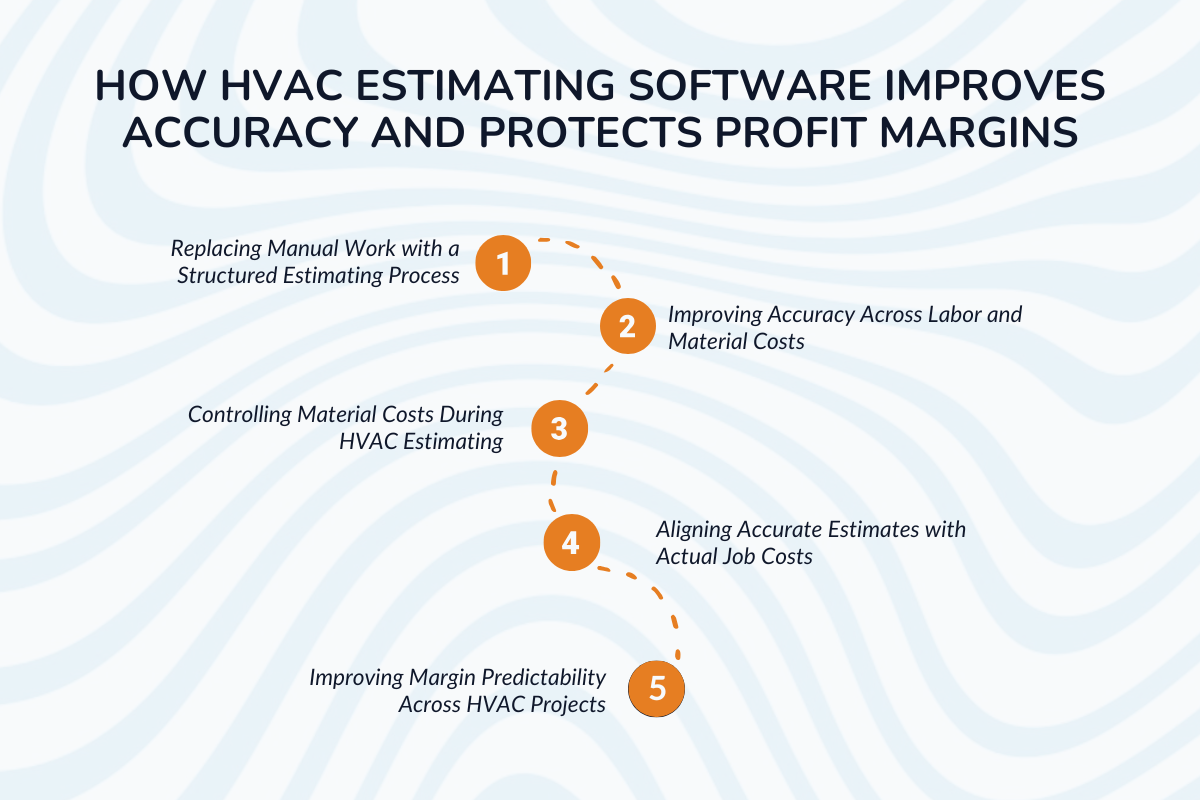

How HVAC Estimating Software Improves Accuracy and Protects Profit Margins?

Accurate estimates are essential for profitable projects. Digital estimating tools replace manual guesswork with a structured approach, helping teams improve cost accuracy and protect margins as workloads grow.

1. Replacing Manual Work with a Structured Estimating Process

Relying on spreadsheets or handwritten notes slows down estimating and introduces mistakes. Switching to a structured estimating system ensures consistency across all projects and saves valuable time.

Benefits:

- Standardized templates to reduce repetitive work and maintain uniform pricing.

- Automates calculations to eliminate human errors

- Keeps all data centralized for easier updates and team collaboration

2. Improving Accuracy Across Labor and Material Costs

Accurate labor and material estimates are critical for avoiding unexpected cost overruns. Estimating software pulls real-time labor rates and updated supplier prices into every estimate, reducing guesswork and improving reliability.

Advantages:

- Labor costs stay up-to-date and precise

- Material and equipment pricing reflects current market rates

- Less risk of missing key line items in the estimate

3. Controlling Material Costs During HVAC Estimating

Material expenses are a major source of lost profit. The software that tracks costs and updates supplier prices helps teams prevent over- or underestimating and keeps projects on budget.

Key outcomes:

- Prevent over-ordering and reduce material waste

- Quickly adjust estimates for price changes

- Protect project margins from fluctuating material costs

4. Aligning Accurate Estimates with Actual Job Costs

Comparing estimates with real job data allows teams to identify gaps early and improve future bidding accuracy. This alignment reduces rework and ensures profitability.

Benefits:

- Spot discrepancies between planned and actual costs early

- Use historical data to refine future estimates

- Track labor, equipment, and overhead to maintain margin control

5. Improving Margin Predictability Across HVAC Projects

Clear cost insights make it easier to determine which projects are truly profitable. Reliable estimates reduce the risk of losing money on jobs that appear profitable on paper.

Best practices:

- Forecast profitability before bidding – evaluate margins before submitting a quote

- Avoid “profitable on paper, loss in reality” jobs – identify high-risk projects early

- Make better bidding decisions – focus on jobs that provide sustainable profits

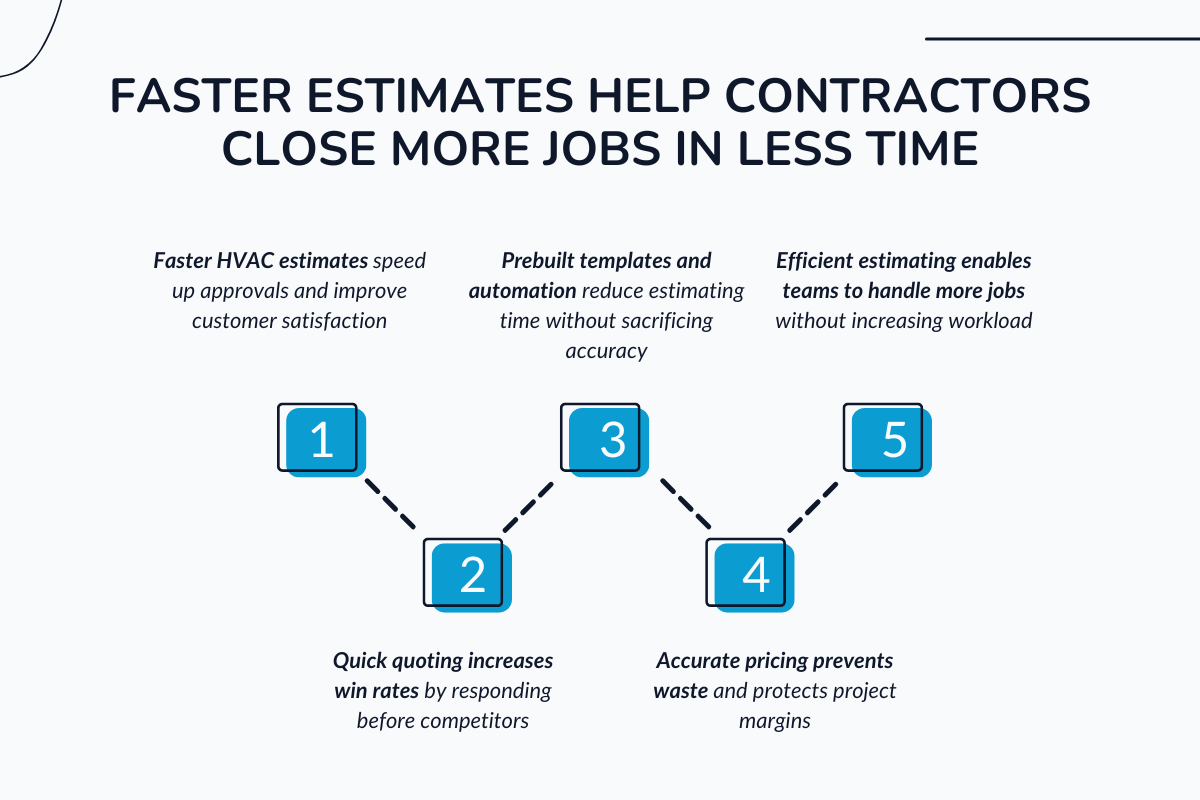

How Faster Estimates Drive Growth in HVAC Businesses?

In HVAC markets, efficiency and accuracy really matter. The quick, precise estimates help service teams manage growing workloads without compromising client trust.

So, how can you improve efficiency and enhance the reliability of your quoting process?

Managing multiple projects doesn’t have to mean longer estimating hours. Modern estimating tools allow teams to scale operations efficiently while keeping the process fast and accurate.

A. Prebuilt Templates Inside Estimating Software

Ever feel like your team is rebuilding the same estimate again and again?

That repetition wastes time and increases the chance of inconsistency. Prebuilt templates solve this by giving estimators a reliable starting point for common HVAC jobs.

Instead of rethinking labor, materials, and pricing every time, teams can adjust proven templates to match the project scope and move faster with confidence.

This approach keeps pricing aligned across similar projects while allowing flexibility where it actually matters.

B. Automated Takeoffs and Calculations

So, where do most estimating errors come from? Manual math and rushed calculations. Automated takeoffs and calculations remove that pressure by handling the heavy lifting for your team:

- Material quantities are calculated automatically based on project inputs

- Labor requirements are applied consistently across estimates

- Fewer manual entries mean fewer costly mistakes

- Estimates are completed faster, even during peak workloads

C. Reducing Waste and Pricing Errors

Outdated pricing and guesswork often lead to over-ordering, missed costs, or uncomfortable margin surprises. When estimates are built on accurate, current data, teams gain real control over project costs.

Instead of reacting to problems mid-job, contractors can plan better, order smarter, and protect margins from the start. That clarity reduces stress across both office and field teams.

D. Increasing Win Rates Without Sacrificing Margins

Winning more jobs shouldn’t mean racing to the bottom on price. Faster, more reliable estimates help teams respond quickly while staying profitable.

Key outcomes teams see include:

- Quicker turnaround on bids without rushing decisions

- More confidence in pricing accuracy

- Better balance between competitive quotes and healthy margins

- Higher approval rates from customers who value clarity and professionalism

When estimates are both fast and dependable, teams don’t have to choose between growth and profitability.

Why Efficiency Matters in HVAC Cost Estimation?

Even small delays in HVAC cost estimation can cost time, affect pricing decisions, and impact profitability.

Have you noticed how slow quotes can affect project approvals and customer satisfaction?

- Faster responses improve bid success rates.

- Quick estimates prevent lost opportunities and keep customers satisfied.

- Efficient quoting helps service providers handle more projects in competitive HVAC markets.

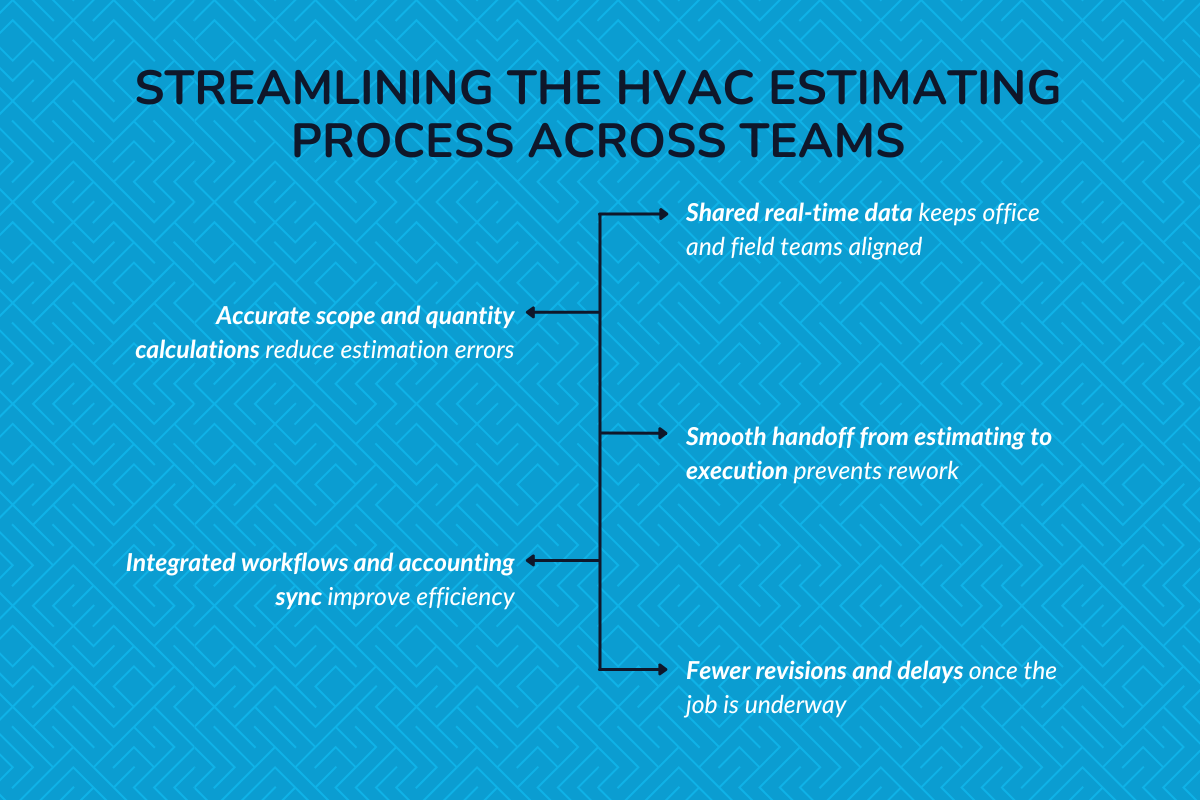

How does streamlining the HVAC estimating process across the team help them?

Strong project outcomes depend on more than calculations alone. They rely on clear coordination between office staff and field crews.

The following section explains how improved coordination supports smoother operations across multiple HVAC projects:

1. By Improving Coordination Between the Office and the Field

When teams work from disconnected files or outdated numbers, even small gaps can slow down projects.

A shared system keeps office staff and field crews aligned from the first calculation to final execution, helping everyone work from the same data across active projects.

Key capabilities that support alignment:

- Centralized access to estimate data so updates are visible in real time

- Faster collaboration between trades handling duct layouts, fittings, and materials

- Seamless integration with QuickBooks to keep costs, invoices, and financial data in sync

- Standardized processes that scale easily as projects and customers increase

- Improved workflow efficiency in approvals and revisions, reducing back-and-forth communication

This shared visibility reduces miscommunication and helps teams create accurate scopes before work begins. Fewer revisions are needed once the job starts, allowing crews to focus on execution instead of corrections.

2. By Reducing Rework Caused by Estimation Errors

Even minor estimation gaps can lead to costly rework, delayed timelines, and strained customer trust. Improving accuracy early helps teams simplify workflows and avoid downstream issues during installation and inspections.

By improving how information flows from planning to execution, teams can calculate quantities more precisely and maintain consistency across all project stages.

Important features that minimize errors and rework:

- Tools to calculate duct runs, fittings, and material quantities accurately

- Clear scope visibility that helps create reliable handoffs between teams

- Data-driven checks that catch inconsistencies before work begins

- Faster estimate-to-payment transitions that reduce manual entry

- Built-in integration with accounting and project tools to support connected processes

- Scalable workflows that adapt as markets, teams, and project volumes grow

A clear comparison of the benefits and drawbacks is provided in HVAC Software vs Manual Estimation: Pros & Cons.

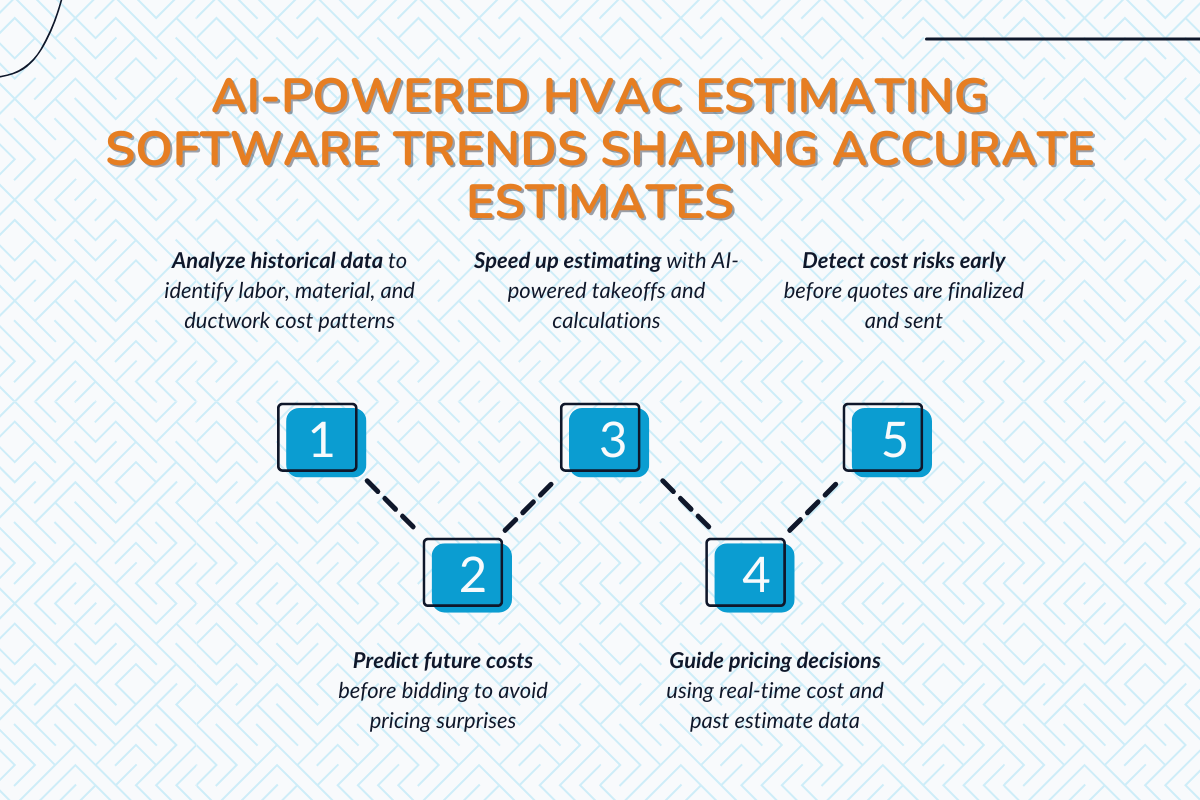

AI-Powered HVAC Estimating Software Trends Shaping Accurate Estimates in 2026

As HVAC projects grow larger and timelines tighten, relying only on manual inputs limits both accuracy and scalability. AI-powered HVAC estimating software is reshaping how teams prepare estimates, analyze costs, and respond to market changes.

In 2026, these tools go beyond speed. They help HVAC businesses reduce risk, protect margins, and make better decisions across services.

1. Predictive Insights for Smarter Estimating

Predictive insights analyze historical estimating data to uncover patterns in labor rates, material pricing, and ductwork complexity. Instead of reacting after a project starts, teams can adjust estimates earlier with greater confidence.

Predictive insights answers: How can teams identify cost risks before they turn into overruns? This shift helps contractors handle more work without sacrificing accuracy or control.

Why this matters:

- Anticipates labor and material cost changes earlier

- Reduces last-minute estimate revisions

- Supports higher estimate volumes without slowing teams down

2. AI-Powered Assistance for Estimating Tasks

So what actually changes in day-to-day estimating work?

Instead of jumping between spreadsheets, takeoff tools, and pricing sheets, AI-powered HVAC estimating software brings everything into one connected workflow.

Estimators receive intelligent support as they build, adjust, and finalize estimates, reducing manual steps and cognitive load. This makes it easier to move faster without sacrificing accuracy, especially when managing multiple projects or service types at once.

A. AI-Driven Pricing Guidance

Pricing decisions no longer rely only on static rate cards or gut instinct.AI-powered pricing guidance uses real-time labor costs, material trends, and historical estimates to support better pricing decisions as quotes are built.

What this improves:

- More balanced pricing between competitiveness and profit

- Better response to market price fluctuations

- Stronger margin protection across bids

B. Pre-Quote Cost Risk Detection

Another growing trend is identifying cost risks before quotes go out the door.

AI systems can flag potential issues tied to equipment complexity, ductwork layouts, labor availability, or material volatility during the estimating stage. By highlighting these risks early, teams can adjust scope, pricing, or timelines before committing to a quote.

This proactive approach reduces margin erosion and helps avoid projects that look profitable on paper but carry hidden risks.

3. Automated Takeoffs With Computer Vision

Estimating no longer starts with manually tracing plans or counting elements line by line. New AI-driven tools can read drawings and PDFs directly, identifying duct runs, vents, equipment placements, and measurements automatically.

HVAC Estimating Software Impact on Financial Performance

The way estimates are prepared directly affects profitability. Manual methods often leave room for missed costs and inconsistencies, while modern software introduces structure, visibility, and control.

The table below highlights how the shift impacts key estimating areas and overall financial performance.

| Estimating Area | Manual / Basic Estimating Process | Estimating Software Advantage |

|---|---|---|

| Estimate Accuracy | Often prone to human error, overlooked costs, and miscalculations. | Uses standardized data and logic to create reliable, repeatable estimates. |

| Material Costs | Pricing may be outdated, inconsistent, or misrecorded. | Automatically updates material costs to protect margins and reduce loss. |

| Estimating Time | Requires multiple calculations, cross-checks, and revisions. | Speeds up calculations with templates and automated processes. |

| Job Volume | Limited by team capacity and manual effort; hard to scale. | Handles more jobs efficiently without increasing workload or errors. |

| Financial Performance | Margins and profitability fluctuate due to inconsistent estimates. | Provides real-time insights to control costs and improve project profitability. |

From Cost Planning to Profitability: Leveraging Estimating Platforms

Estimating is no longer just about calculating numbers; it plays a direct role in long-term profitability. When costs, scope, and pricing are aligned early, businesses gain better control over margins and project outcomes.

1. Reducing Cost Leakage Across Projects

Cost leakage often starts with minor oversights that compound as projects move forward. Centralized estimating tools improve visibility into materials, labor, and scope, helping teams maintain tighter cost control from day one.

Key outcomes include:

- Better cost control from day one

- Fewer surprises during execution

2. Balancing Competitive Pricing with Sustainable Margins

So, how can teams stay competitive without undercutting profitability? Modern estimating tools support data-driven pricing decisions that balance market expectations with realistic cost structures.

A. Confident pricing backed by precise estimates

Build pricing with confidence using precise estimates that reflect real labor, material, and execution requirements, reducing the risk of underpricing or margin erosion.

B. Consistency across all HVAC estimating activities

Maintain consistent pricing, scope definitions, and workflows across all cost estimation activities, ensuring reliable outcomes as teams scale and handle more projects.

A detailed look at streamlining operations is shared in HVAC Software for Service Contractors: Automating Dispatch, Billing & Customer Management.

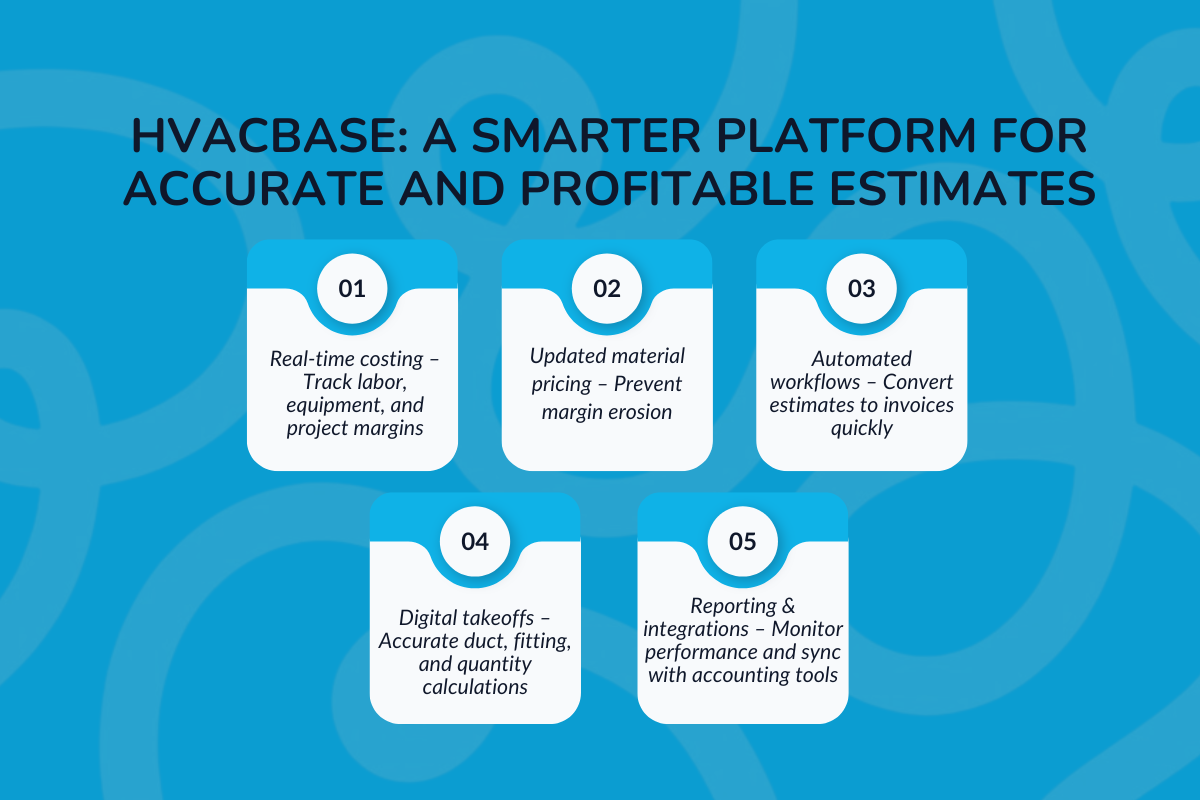

How Purpose-Built Estimating HVACBase Software Supports HVAC Teams?

Rather than juggling spreadsheets and disconnected tools, HVACBase brings estimating, costing, and workflow management into a single, purpose-built platform for HVAC contractors.

It’s designed to improve estimate accuracy, speed up turnaround times, and give teams clear visibility into profitability from bid to payment.

Key features include:

- Real-time job costing and profitability insights: Track labor, equipment, ductwork, and indirect costs per project to understand true margins before and after the job is won.

- Up-to-date material pricing intelligence: Maintain accurate pricing for HVAC equipment, fittings, and materials to avoid margin erosion caused by outdated cost data.

- Seamless estimate-to-invoice workflows: Convert approved estimates into invoices or payment requests automatically, reducing manual errors and billing delays.

- Advanced takeoff and scope management: Perform precise digital takeoffs for duct runs, fittings, and quantities directly from plans, minimizing scope gaps and rework.

- Actionable reporting and performance tracking: Monitor estimate accuracy, win rates, and cost variances to refine pricing strategies and improve bid success.

- Easy integration with accounting and business tools: Sync estimating data with accounting and operational systems to streamline workflows and support business growth.

Final Thoughts

HVAC estimating software plays a crucial role in improving profit margins by bringing accuracy, speed, and consistency to the estimating process.

By reducing manual errors, optimizing material and labour costs, and helping teams bid smarter, it enables HVAC businesses to protect margins while staying competitive.

When used effectively, HVAC estimating software doesn’t just support better estimates; it drives more profitable projects and long-term growth.

Boost Profit Margins with HVACBase

See how HVACBase helps improve estimate accuracy and protect overall profitability.

Book a demo and experience smarter HVAC estimating in action.

FAQs

1. What is estimating software for HVAC contractors?

Digital estimating tools are designed to help contractors generate precise cost estimates for labor, equipment, and project resources while optimizing workflows and increasing profitability.

2. How do digital estimating tools improve estimate accuracy?

It leverages standardized data, automated calculations, and updated material costs to reduce errors, missed items, and estimate inconsistencies.

3. Can digital estimating tools save time on projects?

Yes. Features like prebuilt templates, takeoff tools, and one-click quote generation speed up estimating, allowing teams to handle more jobs efficiently.

4. Does it help track profitability?

Absolutely. By comparing estimated costs with actual labor, material, and indirect cost data, businesses can monitor profitability and make informed pricing decisions.

5. Can field technicians use the software on-site?

Many modern solutions support offline mode and mobile access, enabling technicians to log job details, takeoffs, and invoices even without internet coverage.

6. Are estimating platforms suitable for small businesses?

Yes. Solutions scale to teams of any size, delivering benefits such as improved cost visibility, faster estimates, and accurate pricing without adding complexity.

Have questions or need personalized advice?

Talk to an Expert Today and let our construction specialists guide you to success.