HVAC Estimate Mistakes to Avoid

Running an HVAC business means getting your estimates right – it’s really that simple. But we all know mistakes happen, and they can end up costing you more than just time or money; they can lose you customers, too.

Whether you’re just starting with HVAC estimates or looking to sharpen your skills, knowing the common slip-ups to avoid can make a huge difference.

In this blog, we’ll walk through the typical HVAC estimate mistakes and share easy tips to help you steer clear of them. The goal? To ensure your quotes win you more jobs in various HVAC projects, keep your customers smiling, and help your business grow without stress.

When your estimates are spot on, you build trust with your clients and set clear expectations right from the beginning. That way, there are no surprises later on.

By dodging these common HVAC estimating errors, you’ll save yourself headaches, work more efficiently, and earn a solid reputation in the HVAC world.

5 Common HVAC Estimating Mistakes (And How to Avoid Them)

Let’s be real about HVAC estimating. It’s not always neat and tidy like the perfect scenario where everything goes smoothly. Sometimes your tech is stuck across town, and the customer suddenly wants a bigger unit.

In those moments, getting your estimates right isn’t just another task to check off; it’s what protects your profit, builds trust, and keeps customers coming back.

When your estimates are clear and accurate, everything runs more smoothly: jobs stay on schedule, materials arrive when they should, and your crews know exactly what success looks like.

This guide will walk you through the standard commercial HVAC estimating mistakes, how to fix them, and simple scripts you can start using today. Whether your team works on straightforward residential AC replacements or handles big commercial projects, the goal stays the same: control costs, avoid errors, and win more bids without cutting into your margins.

Key Takeaways

- Even small estimating errors can quickly eat into profit margins. Knowing the most common pitfalls helps you stay ahead.

- Proper preparation and accurate on-site assessments are critical to prevent surprises and keep projects on schedule.

- Clear scopes, documented assumptions, and smart proposals make your estimates easier for customers to understand and approve.

- Calm, confident door-knocking, discovery questions, value framing, and clear explanations help overcome price objections and increase conversions.

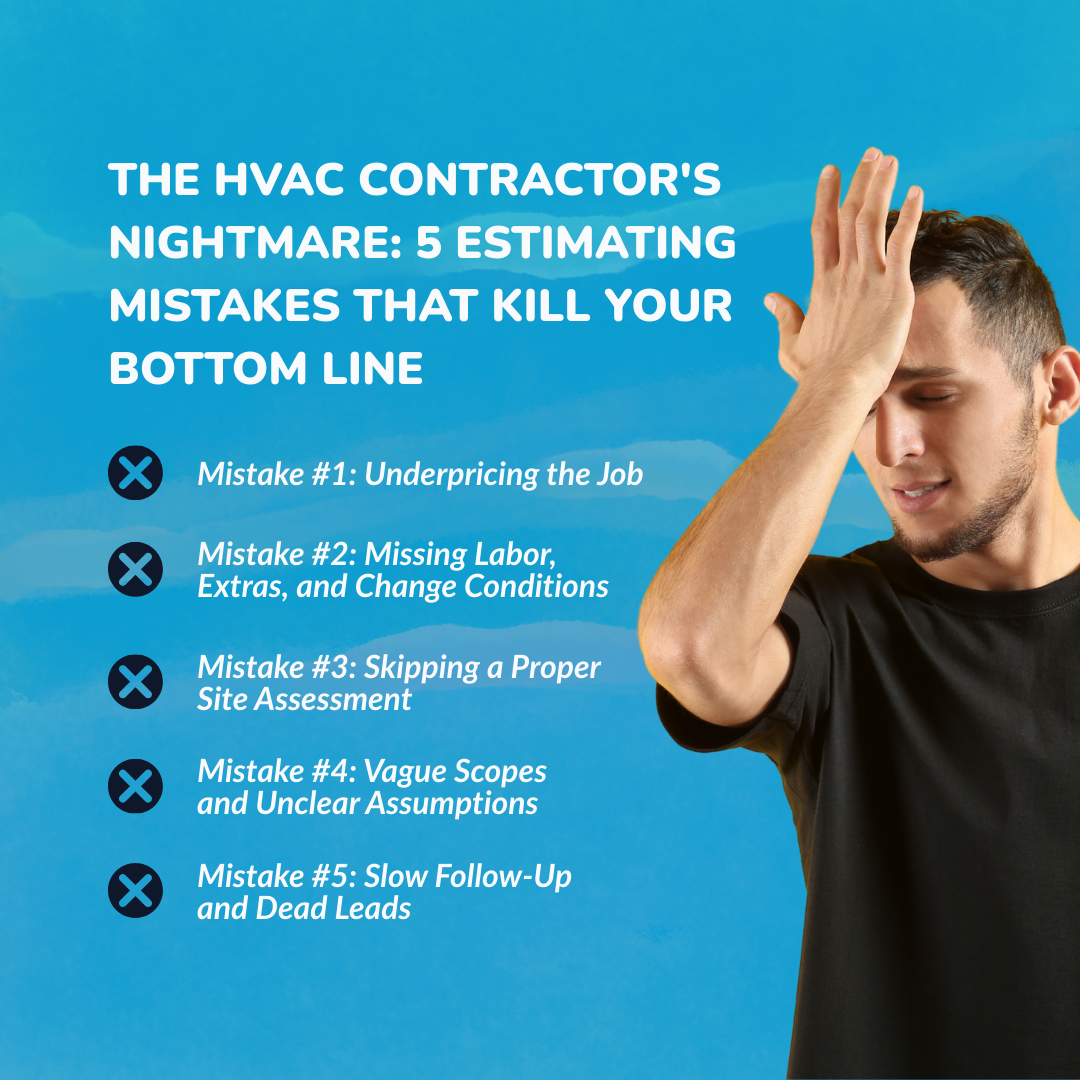

The HVAC Contractor's Nightmare: 5 Estimating Mistakes That Kill Your Bottom Line

Every HVAC contractor knows the sinking feeling of winning a bid only to watch their profit margins disappear during installation.

The culprit? Estimating mistakes that seem small upfront but turn into major financial headaches once the work begins. It leaves contractors scrambling to cover unexpected costs and wondering where their carefully calculated profits went.

Mistake #1: Underpricing the Job

Underpricing is the quickest way to secure more bids, but it ends up losing money in the process. It occurs when many contractors race to the bottom to beat a competitor’s number, forget overhead costs, or overlook travel and returns that quietly consume time.

Sometimes it’s optimism. Sometimes it’s a rushed estimating process. Either way, the outcome is the same: thin profit margins, rising costs, scope creep, and installations that feel rushed.

- What causes it: chasing the lowest bid, missing overhead, ignoring returns and travel, or using generic labor rates that don’t match the actual labor hours on your crew.

- Risks: wafer-thin margins, last-minute “freebies,” warranty headaches, and rushed installation quality.

Fix it with structure and visibility:

- Preloaded Cost templates for equipment, labor tiers, ductwork, and add-ons. Make sure HVAC units, materials, and labor rates are preloaded with current pricing so the total cost isn’t a surprise.

- Built-in Overhead & Profit Presets in the HVAC industry. Baked-in markups, fees, and contingency help cover unforeseen expenses without manual math.

- Present tiered options with clear value framing so customers see choices instead of treating your estimate like a single number to negotiate down.

Door-Knocking Pitch That Works:

- “We’re usually not the lowest price. We are the team that gets the job done right the first time. Our estimates include everything it takes to meet your project specifications, so there aren’t surprises or shortcuts later.”

Checklist before you hit send:

- Overhead added?

- Margin set?

- Rebate or permit accounted for?

- Travel time included?

- Warranty costs considered?

Mistake #2: Missing Labor, Extras, and Change Conditions

Here’s where many estimates go sideways in HVAC systems: attic work that takes longer than expected, duct modifications that weren't measured, or disposal fees that weren’t included.

When estimating commercial HVAC, consider adding electrical upgrades, controls integration, crane charges, or off-hours rules for a building that requires union labor. These are common mistakes, but they’re also preventable.

Common blind spots:

- Attic access and height challenges, tight mechanical rooms, steep roofs, or asbestos.

- Ductwork modifications, returns that need resizing, and fittings that require extra labor hours.

- Electrical changes, condensate pumps, crane fees, and hauling/disposal.

Hidden labor drains:

- Callbacks from unclear scopes.

- No-access returns when nobody’s home or a gate is locked.

- Parts run because accessory lists weren’t complete.

Fix it with clarity and checklists:

- Line-item labor templates task and difficulty. Account for duct, ventilation, and electrical functions with realistic labor costs and labor rates.

- Preload accessory lists and upsell bundles in your estimating software to streamline the process. Add smart thermostats, filtration, or IAQ add-ons that customers often want once they see options.

- Job condition flags in the estimate. Tag tight access, steep roof, or special requirements so the crew and the customer are aligned.

Script for setting expectations:

- “We’ll call out all labor and material costs that could affect the final number. If we find a return restriction or duct leak during assessment, we’ll show you photos and pricing before we proceed.”

Checklist:

- Site access clear?

- Attic height and pitch recorded?

- Electrical upgrades needed?

- Permits and disposal are listed?

Mistake #3: Skipping a Proper Site Assessment

Skipping the assessment can lead to costly rework later. Load sizing guesses, airflow issues, duct leaks, and return restrictions lead to comfort complaints, high energy bills, and warranty pains.

In commercial projects, overlooked details in mechanical rooms, controls, or roof penetrations can significantly increase project costs and timelines.

What gets missed:

- Key considerations include load sizing, duct condition, return path restrictions, clearance for new HVAC systems, and code-driven ventilation requirements.

- Real equipment pathways for installation, including crane access and staging for larger units.

Consequences:

- Comfort problems, noisy systems, longer cycles, and unexpected costs.

- Rework that eats profit margins and erodes customer trust.

Fix it with field-first detail:

- Use load calculation tools and measurement prompts in a mobile app. Capture photos and notes during the visit so the estimating process reflects reality.

- Required photo set includes electrical panel, return, outdoor pad, line set, thermostat, attic, roof, and any special access areas.

“Measure-first” trust builder:

- “We take a few extra minutes to measure and photograph key areas. It helps us give you a complete estimate and avoid surprises during installation.”

Checklist:

- Load calc completed?

- Duct condition noted?

- Clearance and access confirmed?

- Venting and drain routes mapped?

If you are really curious about how HVAC software works, just go through this: How Commercial HVAC Service Software Streamlines Fieldwork

Mistake #4: Vague Scopes and Unclear Assumptions

Vague scopes cause the classic “I thought that was included” moment, which often leads to change-order arguments or negative reviews.

Many contractors assume the customer understands what “standard installation” covers, and customers rarely do. Moreover, commercial clients expect precise project scope language and documentation of inclusions and exclusions.

Symptoms:

- Misaligned expectations, change-order fights, and low satisfaction.

- Crews arrived without the necessary materials because the scope was unclear.

Fix it with clarity and visuals:

- Write explicit scope descriptions with inclusions and exclusions. Add warranty terms, lead times, and any special requirements for the system changeout.

- Use visual proposals that include equipment specifications and side-by-side comparisons to help customers understand the differences between tiers.

Plain-language script:

- “Here’s what’s included in this package and what isn’t. If we run into something unexpected, we’ll show you photos and discuss options before any extra work starts.”

Checklist:

- Warranty terms spelled out?

- Scope bullets clear?

- Exclusions listed?

- Timeline and permits noted?

- Rebates identified?

Mistake #5: Slow Follow-Up and Dead Leads

Hot leads cool fast. A great estimate can sit unread if nobody follows up on it. That’s how more bids slip to competitors who respond sooner or communicate more clearly.

The problem:

- Proposals sitting in inboxes without a reminder.

- Leads are not progressing through the pipeline, so the team is never aware of where deals get stuck.

Fix it with lightweight automation:

- CRM pipelines with stage tracking utilize SMS follow-ups, proposal view alerts, and auto-reminders to maintain the conversation.

- Shorten the quote-to-install workflow with mobile approvals that let customers sign directly from their phone.

Two-touch follow-up script:

- “Just checking in to see if you had any questions on the estimate I sent yesterday. I can hop on a quick call to walk through the options.”

- “If it’s helpful, we can reserve an install window now and adjust if needed. Want me to pencil you in?”

Checklist:

- Quote sent the same day?

- First follow-up within 24 hours?

- Second nudge within 72 hours?

Bonus: Common mistake that everyone makes: Ignoring Seasonality and Market Price Shifts

Quotes built on last season’s pricing will bite you as material costs can shift, fast lead times and equipment availability can change.

If your price book isn’t updated or your proposal doesn’t reflect current lead times, you’ll spend hours re-quoting or appeasing frustrated customers.

Fix it with live data:

- Sync price books to supplier catalogs and inflation updates in your estimating software.

- Add lead time notes and alternative equipment options in the proposal so customers have choices if timing is critical.

Script for price changes:

- "Prices and lead times moved this season, and we’ve reflected that here. If you’re flexible on brand or model, we can install sooner or save you money with an alternate.”

Checklist:

- Is the material pricing current?

- Lead time disclosed?

- Alternatives included?

Tools That Prevent Estimating Errors

The right tools don’t replace good judgment. They make it easier to apply it consistently at speed. HVAC estimating software and a tight field workflow reduce human error and help many contractors present accurate bids that hold up in the field.

Estimating software essentials:

1. Accurate Estimating Tools: Load calculations, up-to-date price books, labor presets, and permit or rebate libraries help you build accurate estimates quickly. So every proposal reflects real numbers, current pricing, and the right rules baked in.

2. Mobile Documentation: Photo capture, notes, and checklists inside a mobile app so the office and field see the same details. Snap, tag, and sync everything on-site so no detail gets lost between the truck and the desk.

3. Streamlined Proposals: A proposal builder with good, better, best options and e-sign keeps the entire process moving. Offer clear tiers, win the “why,” and get approvals on the spot without printing a thing.

4. CRM for Lead Management: CRM with clear follow-ups, pipeline tracking, and reminders to win more jobs. It helps know who’s ready, who needs a nudge, and never let a solid lead go cold again.

5. Seamless Accounting Integration: Accounting sync for deposits, progress billing, financing options, and final invoicing lets you move money. It moves money smoothly from estimate to paid, without double entry or chasing paperwork.

Field workflow that works:

1. Prepared On-Site Visits: Pre-visit checklist, on-site capture, same-day estimate, and SMS follow-up ensure you arrive prepared, document thoroughly, send the quote the same day, and follow up while interest is high.

2. Accurate Fabrication Handoffs: Handoff steps are documented to ensure fabrication partners gain access to accurate specs early, particularly for ductwork and custom transitions. By sharing clean specs upfront, custom pieces arrive correctly, and installations proceed on schedule.

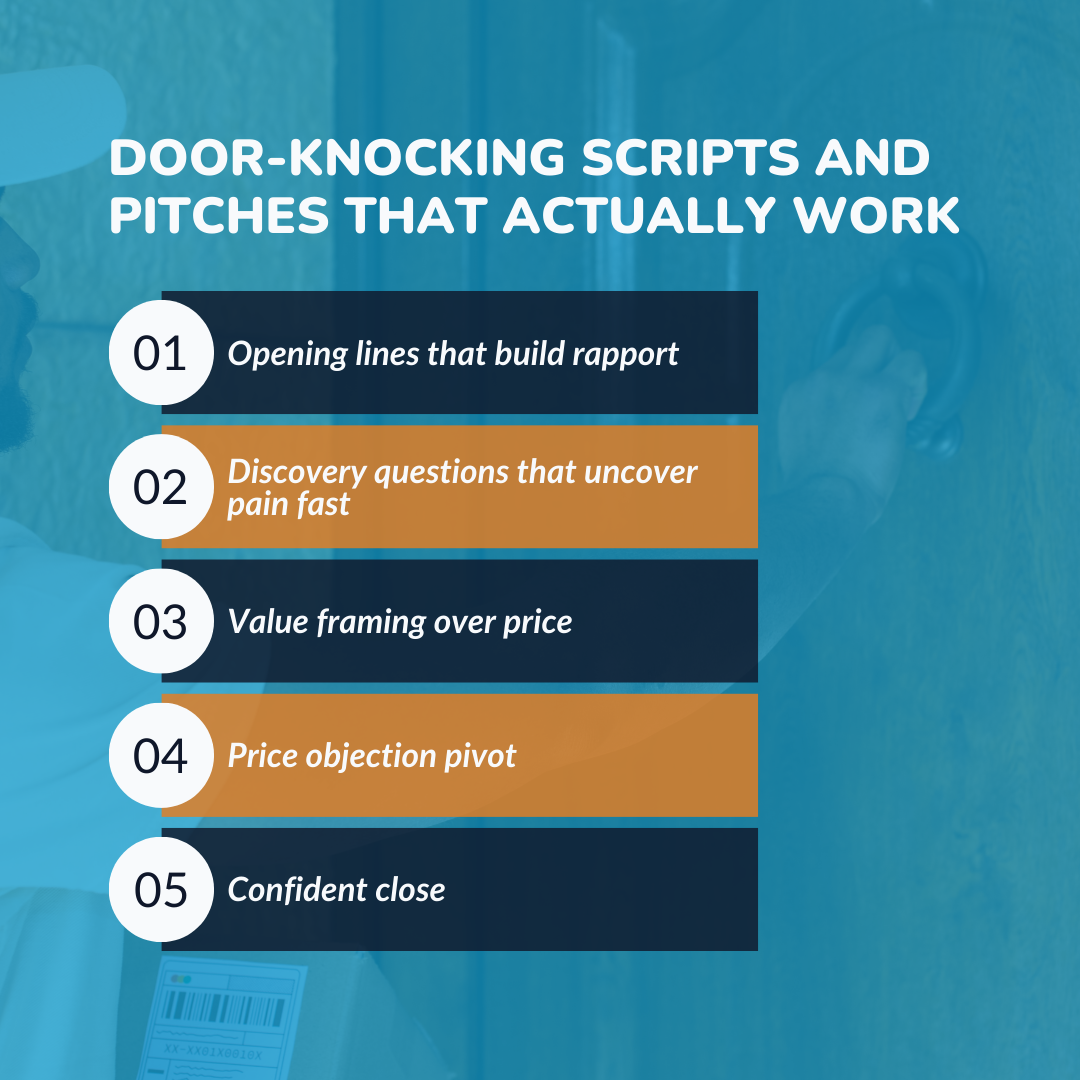

Door-Knocking Scripts and Pitches That Actually Work

Great scripts don’t sound scripted. They sound calm, confident, and helpful. Use these as starting points and make them your own.

Opening lines that build rapport:

- “We’re working with a few neighbors on heating and cooling upgrades. If you’re noticing hot or cold spots, I can take a quick look and share what’s typical in these homes.”

- “We’ve got a few installation windows opening this week. If you’re thinking about air conditioning or a quieter system, I can show you options.”

Discovery questions that uncover pain fast:

- “Where in the house feels uncomfortable during extreme weather?”

- “Have your energy bills changed in the last year?”

- “Any problems with airflow or noise that you want fixed this time?”

Value framing over price:

- “We focus on comfort, reliability, and operating costs. The goal is a system that runs quietly, meets your usage, and doesn’t surprise you on the bill.”

Price objection pivot:

- “We might not be the lowest, and there’s a reason. We build estimates that include everything required for a seamless installation, ensuring no additional costs later. That’s how we protect your warranty and your time.”

Confident close:

- “Would you prefer the standard package or the higher-efficiency model with the longer warranty? I can hold Thursday morning or Friday afternoon for installation.”

If you want to know how HVAC CRM can grow your business, then take a look at this: What is HVAC CRM Software and How Can It Grow Your Business?

Pricing Models That Protect Your Margin

A strong pricing structure protects profit margins while still giving customers choice. The right model depends on job type, customer expectations, and the risk profile of the work.

- Time and materials: Useful for complex diagnostics or unknowns in older structures. Ensure that labor rates are posted and materials are billed accurately.

- Flat-rate pricing: Ideal for common replacements or repairs. So, use detailed scope definitions to avoid ambiguity.

- Tiered value bundles: Good, better, best options highlight key factors like efficiency, warranty length, and comfort features. This approach improves close rates and average ticket size.

When to use each:

- Residential replacements: Flat-rate with tiered bundles is a great fit.

- Light commercial: Hybrid approach with a defined scope and contingency line.

- Retrofits: Utilizing time and materials or a clear change-order process helps cover unforeseen expenses.

Presenting bundles without confusion:

- Keep the differences visible in a simple table. Show operating costs, warranty, sound levels, and what’s included in installation. Avoid jargon. Focus on outcomes.

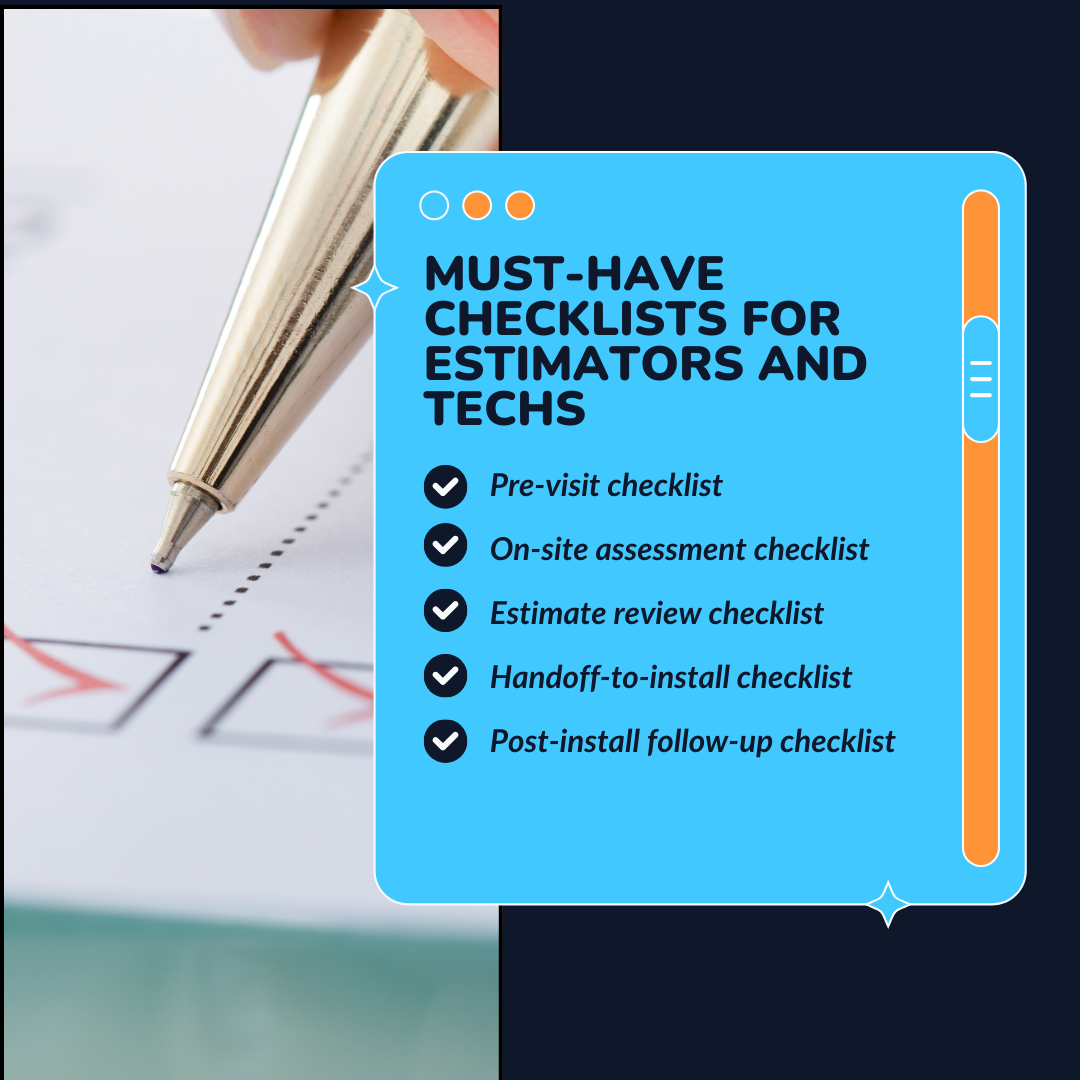

Must-Have Checklists for Estimators and Techs

Checklists maintain consistency in the process, especially when the team expands or new estimators join. They also reduce human error during the estimating process.

1. Pre-visit checklist

Confirm the homeowner’s goals and comfort complaints, record current equipment details and photos, and verify access points, parking, pets, and gate/lock instructions before arriving.

2. On-site assessment checklist

Capture load calculation data, measure ducts and returns, note electrical capacity and venting paths, and take clear access photos to document constraints.

3. Estimate review checklist

Verify that overhead, labor, and material costs are current. Include permits, disposal, warranty terms, realistic timelines, and a small contingency for surprises.

4. Handoff-to-install checklist

Stage equipment and materials, share ductwork fabrication specifications, list any special tools or lifts required, and brief the crew on the scope, risks, and site rules.

5. Post-install follow-up checklist

Commission the system with documented readings, upload completion photos, register warranties, and walk the customer through operation, maintenance, and support.

A well-run HVAC businesses achieve 50-55% gross profit margins, while the industry average hovers around 30-40%, with many struggling companies operating at just 2-3% net profit.

Common Add-ons and Extras to Preload

Preloading common adders saves time and ensures complete estimates, especially when customization and duct modifications are likely.

- Electrical upgrades, pad and line set, condensate pumps, crane and permits, and disposal fees.

- Duct sealing and repairs, return upgrades, smart thermostat, filtration, and IAQ add-ons.

- Warranty upgrades and maintenance plans for long-term customer relationships.

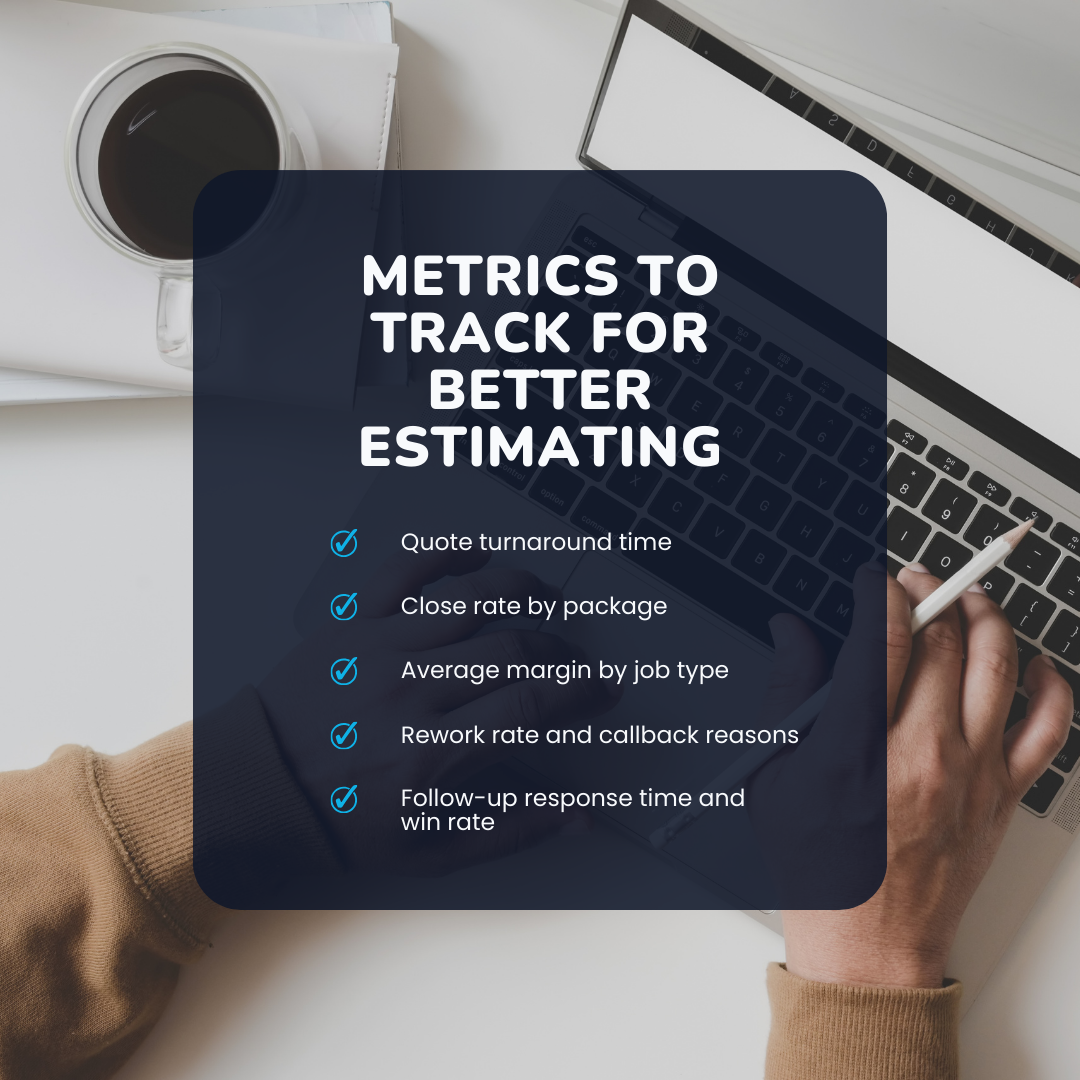

Metrics to Track for Better Estimating

Estimating gets sharper when it’s measured. A few simple numbers reveal where the process needs improvement and where you’re excelling.

1. Quote turnaround time: Send estimates quickly after the visit to maintain momentum and prevent competitors from gaining an edge.

2. Close rate by package: See which option customers choose most to refine your 'good, better, best' bundles and pricing.

3. Average margin by job type: Track profit on residential, commercial, and retrofit jobs so you focus on the winners.

4. Rework rate and callback reasons: Spot patterns in fixes and scope misses to tighten templates and avoid repeat mistakes.

5. Follow-up response time and win rate: Nudge quickly and consistently, because timely check-ins turn solid maybes into signed jobs.

Conclusion

Accurate estimates are the foundation of strong HVAC work. When estimates are detailed, clear, and realistic, the installation team knows precisely what to do, and the office can schedule with confidence. Customers feel they’re getting value rather than vague promises.

Here’s what to do next: adopt checklists, tighten scopes, use the right tools, and follow up fast. That’s how HVAC professionals streamline the entire process with efficiency, from the first site visit to commissioning day.

Precise estimates lead to better projects and better relationships. Keep refining. Keep tracking your numbers. That’s how you build a competitive edge in a challenging process.

Streamline Your HVAC Estimates and Win More Jobs Today with HVACBase.

Experience how HVACBase transforms your business. It simplifies everything and streamlines customer communication on an easy-to-use platform. Book your Demo today!

FAQs

What are the most common HVAC estimating mistakes?

Underpricing, missing hidden labor/materials, skipping site assessments, vague scopes, and slow follow-ups. These cut margins cause delays.

How can HVAC estimating software prevent errors?

It automates load calculations, updates pricing, standardizes labor, captures site photos, builds tiered proposals, and generates more accurate bids.

What should every accurate HVAC estimate include?

Clear inclusions/exclusions, current labor costs and material costs, permits/disposal, warranty, timeline, contingencies, and flagged job conditions.

Have questions or need personalized advice?

Talk to an Expert Today and let our construction specialists guide you to success.